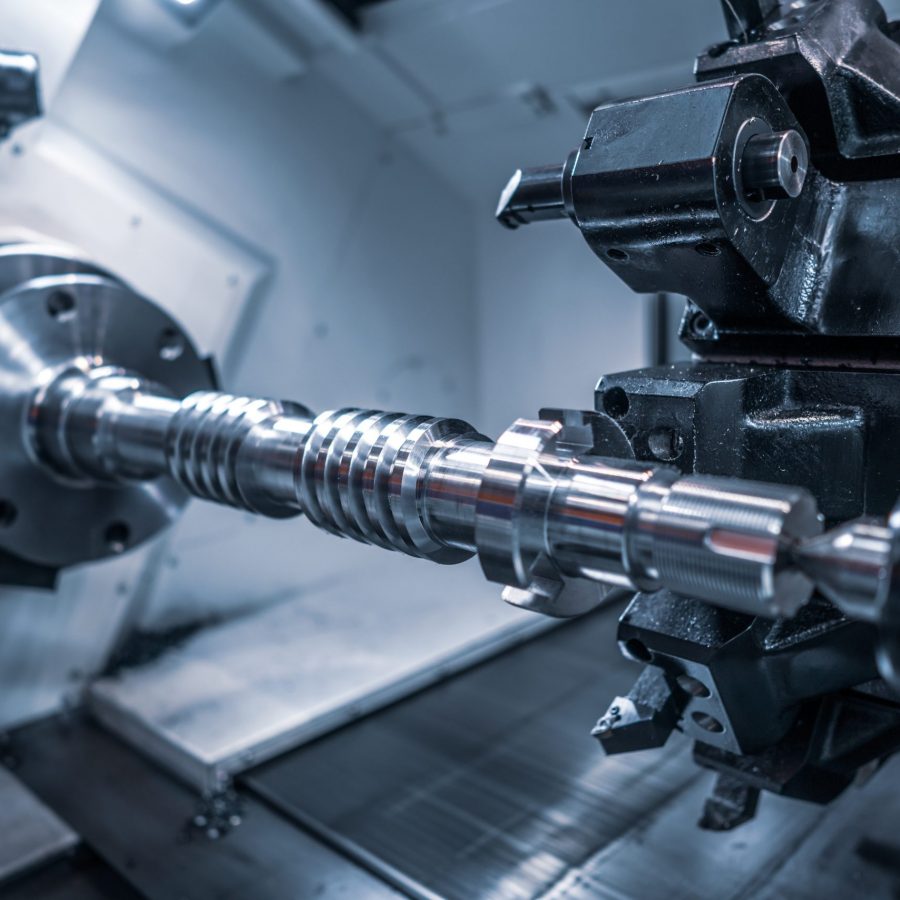

Manual turning

Our machine park is based on proven, precise and reliable devices, as well as our staff that is experienced in manual cutting and carry out individual and highly customised projects. Thanks to our practice and skills acquired during this time, we realize projects with a high level of complexity with a large number of details and we provide design support in preparing turned parts. We realize projects from steel, acid-resistant steel, aluminium, brass and plastics.

CNC turning

Thanks to the numerical lathe we can perform all kinds of individual and unique projects as well as serial production. The high accuracy of the device ensures perfect repeatability of elements, the realization of which may be based on designs provided by the client or a design made by us that meets your needs. CNC turning is perfect for the production of spare parts for all kinds of devices. We realize projects from steel, acid-resistant steel, aluminium, brass and plastics. Turning with the use of numerical devices significantly automates the production process, which in turn reduces costs resulting from reduced production time, especially in the case of serial production.

Manual milling

Thanks to manual machines we are able to produce small series of pieces, this solution is more economical than CNC machines. Experienced specialists who perfectly know their working environment and the characteristics of individual materials processing guarantee manufacturing products at a very high level of precision.

We realize projects from steel, acid-resistant steel, aluminium, brass and plastics

CNC milling

Numerically controlled machines are extremely accurate and repeatable in production. Our experience in milling various materials allows us to manufacture elements with a high degree of complexity and size. We realize projects from steel, acid-resistant steel, aluminium, brass and plastics. In the absence of designs for the ordered elements we provide design support preceded by an interview and measurements, if necessary.

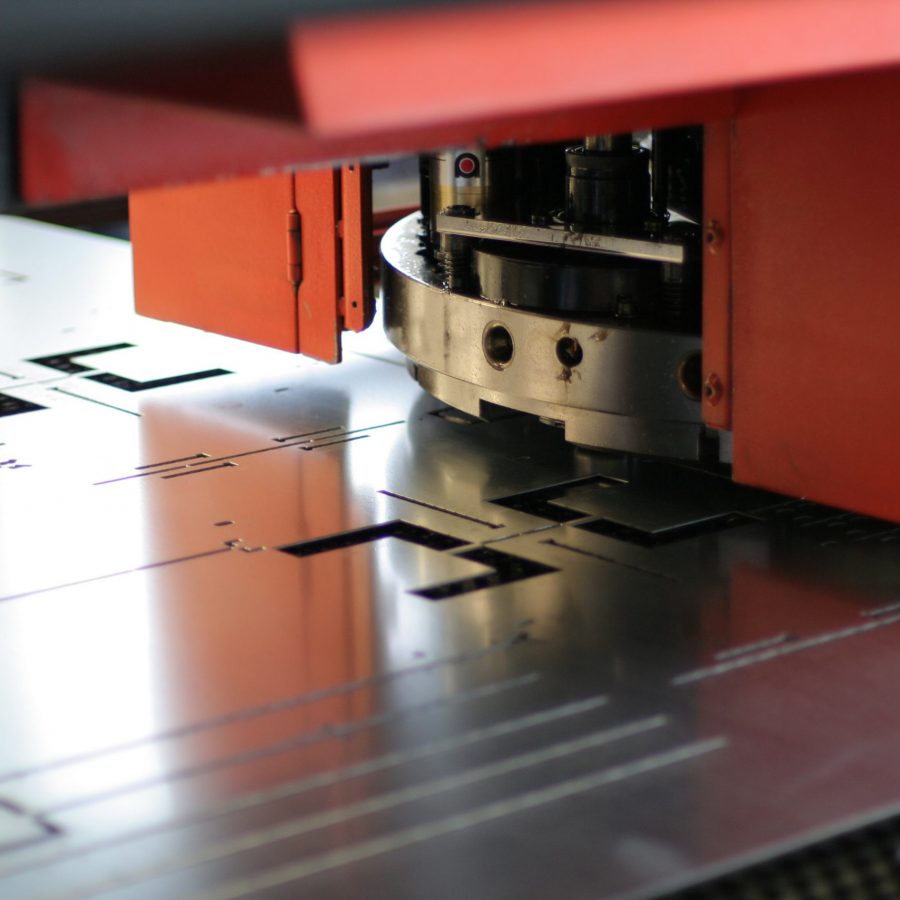

Gas, laser and plasma CNC cutting

Thanks to our numerical gas, plasma and laser cutting technology, we provide services of precise metal cutting and cutting of all shapes. The main advantages of these types of metal separation are high precision of cutting, the ability to cut even thick materials and repeatability of performed operations.

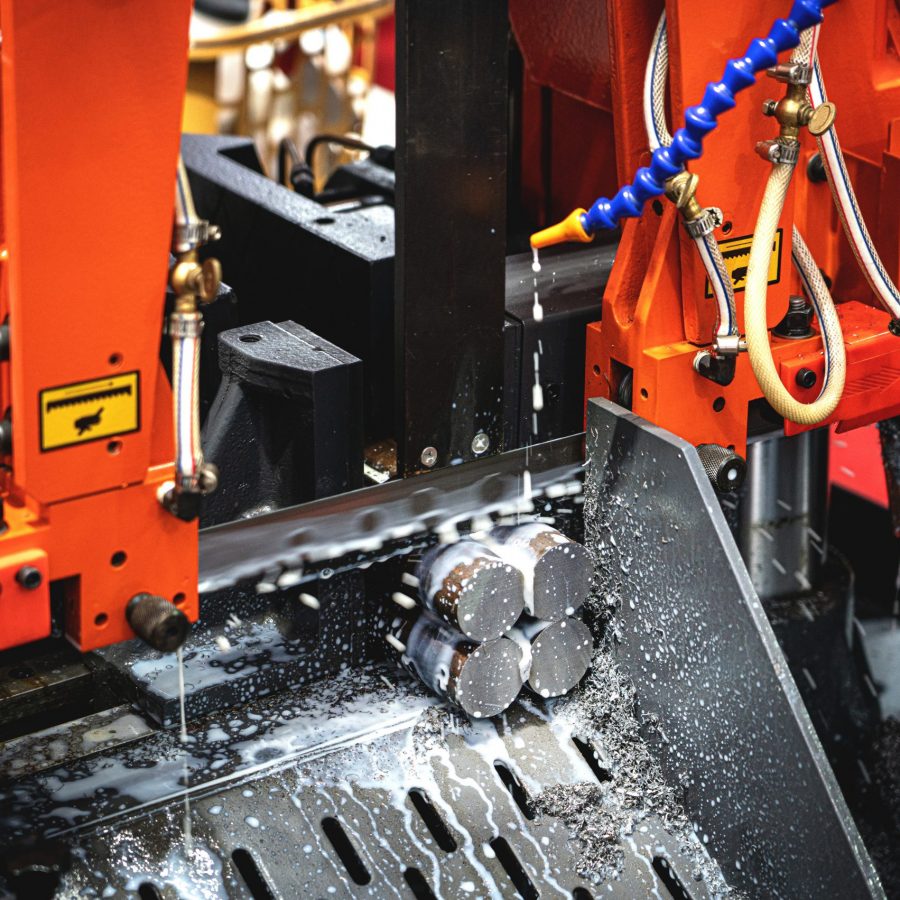

Bandsaw cutting

The bandsaw that we have at our disposal is used mainly for cutting steel elements of considerable size, which cannot be handled by other material separation techniques. The cutting itself is visually appealing thanks to the slow cutting process with not too much force being used. In most cases, a cut made in this way does not require further processing.

Punching and embossing

Our company offers the possibility of punching and embossing in sections and sheets up to 10 mm thick. We have a wide range of sizes and shapes of punches.

Welding

In the metal joining we specialize in welding carbon steel, wear-resistant steel (400 – 500 HB), acid-resistant steel, stainless steel and aluminium. The use the following welding techniques: MIG 131, MAG 135 and TIG 141. Our previous experience allows us to perform demanding connections both technically and aesthetically.